1.OILMICO Objective Introducing

1.1. OILMICO History

Oil Industrial Leading and Manufacturing International Company (OILMICO) have been established dated 18 Jul 2006 in ESFAHAN IRAN. With thought to be synergistic of the technical, performance and experience gained by number of artisans in Esfahan has been formed to help with the activities of oil and gas and petrochemical industry in the following field’s desired objectives are achieved:

Engineering, Procurement, Construction and Commissioning of oil and gas and petrochemical projects (EPCM)

Participation into internal and external oil and gas and petrochemical projects

Feasibility studies, investment in manufacturing machinery and necessities of oil and gas and petrochemical installations

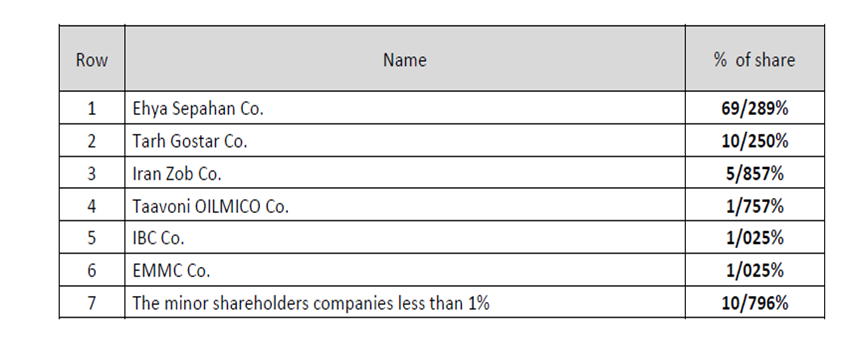

1.2. OILMICO Major shareholders list

1.2. OILMICO Major shareholders list

2. OILMICO Certificates

All certificates all available in website www.oilmico.ir

2.1. Oil and Gas grade II which is for announcement in sajar.mporg.ir

2.2. IMS

With increasing development and the growing trend of international Oil industry engineering and manufacturing corporation to establish management systems in accordance with organizational goals and the demands of their customers and partners, in order to gain the clients satisfaction and upgrade the competitiveness of the management and implementation of oil and gas projects, requirements standards ISO9001: 2008 as quality management system , ISO 14001:2004 as environmental Management System , OHSAS 18001:2007 as an occupational health and safety management system , ISO 29001:2003 as quality management system in oil, gas and petrochemical industries , HSE-MS as health and safety and environment management system and ISO 10668:2010 as the international brand valuation system is selected and implemented.

The organization managers according to the above principle view points, have been established their activities based on a quality management system (ISO 9001 standard) after have been succeed to receive qualify certificate from SGS CB Institute dated 8 December 2009 , and after three years the organization system have been upgraded to IMS from IMQ CB Institute dated 13 March 2013

The benefits of an establishing quality management system in any organization can be implying of the following:

- Improvement process

- Decrease Customer complaints

- Customer satisfaction

- Increase customer confidence

- Improvement productivity and efficiency

- Compliance with environmental problems due to population growth and the depletion of natural resources, this has attracted the attention of organizations.

- Therefore, the establishment of environmental management system ISO 14001 would be included the outcomes and positive results as following:

- Prevent pollution

- Saving electrical energy and fossil

- Optimized use of raw materials and natural resources

- Improvement industrial relations with environment

- Human resource is the most valuable resource of any organization, Cost reduction is the most important means of protecting human resource, organization require regulations to assess and manage the risks or simply manage the risks,

- This matter makes the importance of achieving an Occupational Health management system OHSAS 18001 clear,

Another positive outcome of this system establishment can be as following:

- Provide, maintain and improve physical, mental and social health of employee

- Regard to the prevention accidents related to work

- Reduced costs due to the high risk

- Increase the sense of employee participation and loyalty in the organization

- Enhance the employee productivity and efficiency through attention to ergonomic and mental factors

- The Integrated management system establishment would be included many positive outcomes the most important as following

- Improvement quality services and fulfillment of customer

- Project Implementations and services without any environmental pollution

- Reduce audio, visual, weather and traffic pollution

- Optimization Energy and resources usage

- Improvement health, safety and occupational of the employee and administrative and service personnel

- Prevent of accidents in all activities and services

- Improvement the achieving public’s readiness to deal with emergencies and natural disasters

- Create a sense of responsibility, commitment and compliance and safety regulations

- Create a safe and pollution-free environment in the project site

OILMICO have been announcing commitment to this management system establishing and performed achieving quality objectives based on policies approved by the organization.

2.3. Known managers

2.4. Oil Industries Equipment Manufacturers Association

2.5. ARC for oil, gas and petrochemical management

2.6. contractor first development congress

2.7. Engineering unit establishment approval

2.8. National Production National Honur from Mine and industrial ministery

2.9. 100 top brand from ESFAHAN

2.10. Esfahan industrial university Research agreement

2.11. HSE Activity approval

2.12. Heavy wall pipe factory establishment

2.13. Book Firm of client

2.13.1. NIOC – GACHSARAN Project

2.13.2. PPI – Steel Structure

2.13.3. ICOFC – DALAN Wellhead

2.13.4. POGC – Tank farm – page 1

2.13.5. NIOPDC – Boiler correction consultant

2.13.6. MAPNA – Fan bell – ACC system of Combined Cycle Power Plant

2.13.7. KORC– Tank farm

2.13.8. ESCo – Agglomeration environment pollution preventing

3. OILMICO Capabilities

3.1. Engineering and Technical Capabilities

- Designing and Modeling with Engineering software such as TEKLA, SOLIDWORKS, CATIA, CAESAR II, PDMS, Carrier, ASPEN, E-plan, Matlab, Dialux, WinCC,

- Engineering of processing designs.

- Engineering of Piping design

- Engineering of Mechanical designs.

- Engineering of Electrical

- Engineering of Instrumental designs.

- Planning and control of engineering

3.2. Procurement

- Purchasing Procedure check and control

- Preparation and Handling of Requisitions

- Evaluation of Quotations

- Vendor Documents Review

- Quality Assessment of Vendor

- Packing Procedure and Marking

- Transportation and Shipping

- Planning and control of Procurement

3.3. Construction

- Manual Format and Organization

- Mobilization and Office Administration

- Site Security

- Field Purchasing

- Warehousing

- Subcontracting

- Field Cost Management

- Final Construction Report

- Preparation for Start up

- Piping Inspection

- Welding Procedure

- Welding Material Control

- Control of Testing Equipment

- Planning and control of Construction

3.4. Management

- Management of engineering functions, earthworks, civil, structural,

- mechanical, electrical and instrumentation.

- management of project controls

- management of main contractors and sub-contractors in all disciplines

- management of client supplied equipment and consumables

- management of project safety

- management of project quality

- management of industrial relations

4. Memorandum of Understanding

Cooperation with IRANIAN and foreign consultant companies of Oil and Gas Industries (if necessary).

Some OILMICO agreements are as follow:

4.1.1. NARGAN – Storage and metering system of GAS condensate ASALOUYEH

4.1.2. OTEC – MC Project of Esfahan Refinery

4.1.3. Bani hashem Industries – Construction, installation, and commissioning of spherical, Pressurize, storage tanks

4.1.4. Tech International and Pars Energy – supply crude oil desalting project Gachsaran 3

4.1.5. Behpoyan – recycling Gasoline vapor

4.1.6. Foolad Technic and Energi khavar miyane – Project Gachsaran 3

4.1.7. ESEMERAL – Billet Aluminum Plastic raw material imports

4.1.8. Ircast- Boiler combustion system and Economizer of Esfahan Refinery

4.1.9. DAEWOO and Hyundai steel – Raw material of H-beam

4.1.10. JAHANKAR Co. – Steel structure phase 19

4.1.11. TAHGHIGHAT SEPAHAN – CEMENT Truck for drilling rig pomp

4.1.12. OWETECH china – Drilling rig

4.1.13. OTEC – Extra gas collecting in GACHSARAN Unit 1, 2

4.1.14. RG – Drilling rig

4.1.15. OTEC – ABADAN refinery upgrading

4.1.16. IRCAS SHAVENBERG – Steel structure, furnace, … in general

4.1.17. EDL (Germany)- Optimization engineering studies of Esfahan refinery furnaces

4.1.18. RIPI (Research Institute of Petroleum Industry of IRAN)- Optimization of plant kerosene Esfahan refinery and coordination of implementation of a fully

4.1.19. APS (ITALY)- must cooperate together on the subject of package B of Esfahan refinery’s upgrading project

4.1.20. NARGAN – cooperate for the package C Esfahan refinery

5. OILMICO Projects

5.1. Crude Oil Desalting plant – GACHSARAN 3

The main activities of project:

- Leveling and Fencing of site 60000 SqM

- Construction Industrial and non-industrial buildings with infrastructure 3000 SqM

- Construction stored and pressurized tanks (800 Tons)

- Installation of mechanical equipment (1100 Tons)

- Operation of Execution Pipeline (19 Km)

- Operation of unit Piping (40000 diameter inch)

- Operation of Execution electrical and instrumentation

- Pre-commissioning and commissioning of the project

5.1.2. Client NISOC

5.1.3. General data

- Capacity: 110000 BPSD

- Location: Gachsaran

- Schedule: 36 Month

- Project Start: 2008/02/20

- Project Type: EPC

5.1.4. Duration 36 Month

5.1.5. Total Cost: ~ 20,000,000 EUR

5.1.6. Pictures

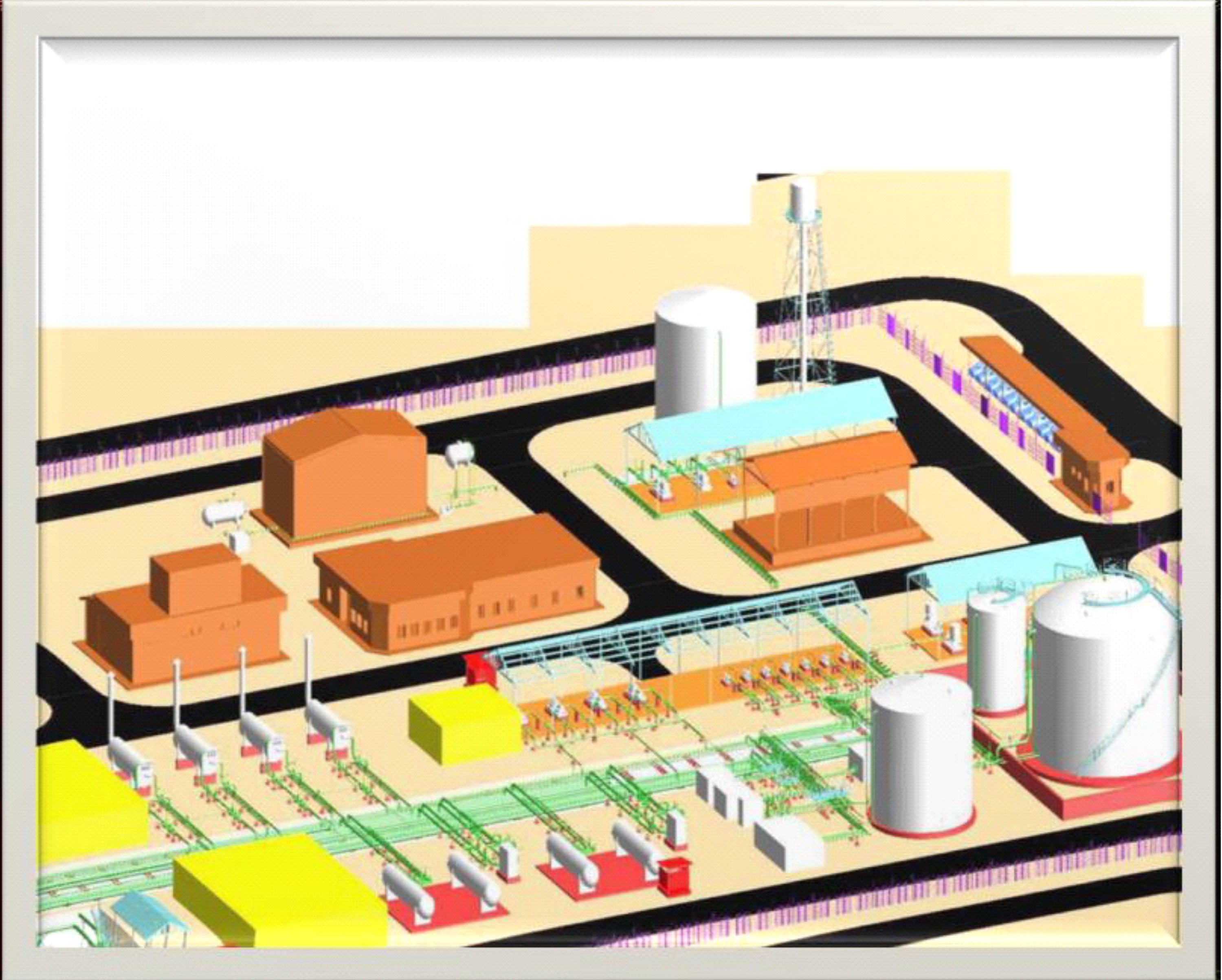

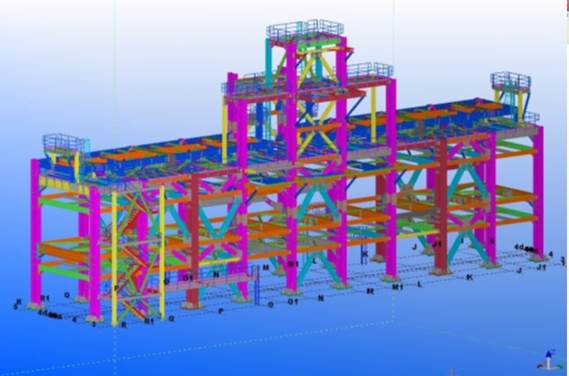

Project Model

In order to minimizing the interfaces between different disciplines and also optimized arrangement in process units, Project model was designed in PDMS.

- PDMS modeling of plant

- Desalter

- Desalter and related piping

- Pump house

- General view of site

- Tank installation activities

- Heater

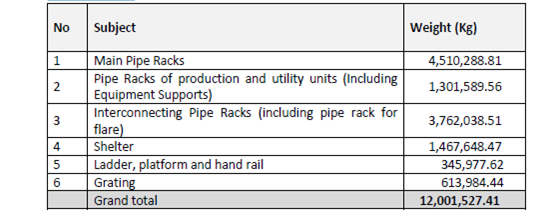

5.2. Process Units Pipe racks – Phase 19

5.2.1. Definition

Supply, Fabrication and Installation Steel Structure South Pars Gas Field Development Project – Phase19

Structure types:

Despite of OILMICO have been developed IMS dated Nov 2013, OILMICO is so glad to announce that “OILMICO don’t have been observed any Incident during the project running.

5.2.4. Duration 10 Months

5.2.5. Total Cost: ~ 32,600,000 USD

5.3. Warehouse Shelter – Phase 19

5.3.1. Definition

Supply seven warehouses and foundation for workshops of support the operation of piping spools.

5.3.2. Client PPI Co.

5.3.3. General data

Material used in these projects was Plate ST37 of Foolad Mobarakeh Company that made to Beam for installation operations. The total amount is 500 Tons structure

Location: Tombak – Kangan – Bushehr Province

Project Start: 2011/08/11

Project Type: EPC

5.3.4. Duration 90 Days

5.3.5. Total Cost: ~ 600,000 EUR

5.3.6. Pictures

5.4. Wellhead Facilities – Dalan Area Nr.1

5.4.1. Definition

The Main Equipment:

- PIPING SIZE ½” – 20” X52 SEAMLESS (2000 Meters)

- PIPE LINE SIZE 8” API 5L X52 SEAMLESS for 3500 Meters

- MANUAL AND AUTOMATIC VALVES SIZE 1”- 16” TYPE 6A & 6D

- FITTING – FLANGE – GASKET – STUD BOLTS

- CHEMICAL INJECTION PACKAGE

- WELLHEAD COTROL PANEL

- CORROSION SYSTEM

- FIELD INSTRUMENT

- ELECTRICAL EQUIPMENTS SUCH AS LIGHTING PACKAGE – TRANSFORMERS

- LV& MV PANEL AND LV SWITCHGEAR

The main activities of project:

- Right of way

- Site leveling & fencing

- Piping & Pipe line

- Electrical Equipment installation

- Instrument Equipment installation

- TEST & Pre commissioning

5.4.2. Client ICOFC

5.4.3. General data

Location: South of Fars Province, Aghar- Dalan region, near to Farrash band Gas refinery.

Project Start: 10 Jul 2014

Project Type: PC

5.4.4. Duration 18 Month

5.4.5. Total Cost: ~ 2,500,000 EUR

- General View

- Wellhead

- WHCP, CIP

- DM2

5.5. Wellhead Facilities – Dalan Area Nr.2

5.5.1. Definition

The Main Equipment:

- PIPING SIZE ½” – 20” X52 SEAMLESS

- PIPE LINE SIZE 8” API 5L X52 SEAMLESS fo 11550 Meters

- MANUAL AND AUTOMATIC VALVES SIZE 1”- 16” TYPE 6A & 6D

- FITTING – FLANGE – GASKET – STUD BOLTS

- CHEMICAL INJECTION PACKAGE

- WELLHEAD COTROL PANEL

- CORROSION SYSTEM

- FIELD INSTRUMENT

- ELECTRICAL EQUIPMENTS SUCH AS LIGHTING PACKAGE – TRANSFORMERS

- LV& MV PANEL AND LV SWITCHGEAR

The main activities of project:

- Right of way

- Site leveling & fencing

- Piping & Pipe line

- Electrical Equipment installation

- Instrument Equipment installation

- TEST & Pre commissioning

5.5.2. Client ICOFC

5.5.3. General data

Location: South of Fars Province, Aghar- Dalan region, near to Farrash band Gas refinery.

Project Start: 10 Jul 2015

Project Type: PC

5.5.4. Duration 18 Month

5.5.5. Total Cost: ~ 4,500,000 EUR

- General View

- WHCP, CIP

5.6. Pipeline from MANSOURABAD to Gachsaran

5.6.1. Definition

The Main Equipment:

- PIPELINE SIZE 20” 35000 Meters ERW

- PIPE LINE SIZE 10” 35000 Meters Seamless

- In unit Piping

- Control valve

- LBV valve

- 4 units Launcher and receiver

5.6.2. Client NISOC

5.6.3. General data

Location: Mansour Abad to Gachsaran

Project Start: 21 Nov 2015

Project Type: PC

5.6.4. Duration 20 Month

5.6.5. Total Cost: ~ 12,000,000 EUR

5.7. Dehloran Wellhead and Pipeline(Locations W036N،W096N,W122N,W140N) as pc contract type

- Client

ICOFC

- Contract has been signed dated 31 Dec 2017 with amount 133,579,812,367 IRR and 4,878,460 EUR

- Project duration: 24 months

- Scope of works

Pipe line, row, wellhead facility, and the total works for transferring the sour oil from well to desalting unit with 66.4 km of pipeline the all material should be prepare and purchase from foreign sources.

The details of scope of work are as below:

– Civil and road

– Pipeline

– Mechanical

– Electrical and power line

– Instrument

– Hydro test and pig running

– Commissioning and cold test

The guarantee duration is 6 month

- Photo of the Progress Dehloran Wellhead and Pipeline

- Photo of the Progress Dehloran Wellhead and Pipeline

- RIGs

5.8.1 2000 HP Electrical land drilling rig complete package – 2 sets

5.8.2 1500 HP Workover land rig complete package – 4 sets

5.8.3 1200 HP Workover land rig complete package – 4 sets

5.8.4 3000 HP Electrical land rig complete package – 1 set

5.8.5 2000 HP Offshore drilling rig complete set – 1 set

- Localization

Oilmico,started to produce and manufacture the drilling land rig localy inparalled of other project.

For this case,oilmico aimed participate in a project of land rig.the 2000 hp land rig selected and oilmico started for this project.

OILMICO selected 30% of IRANIAN local manufacturing and clinet accepted.

- 5.8.1 Land Rig 2000 hp

- 2 sets of land rig 2000hp ordered by kala naft Tehran.

- Main parameters

- 2000 HP Electrical land drilling rig complete package, to be furnished by following major components:

Cantilever mast as per API 4F

Swing up substructure as per API 4F

Drawworks rated input 2000 hp

Drilling depth 20000 ft

Mast height above floor 152 ft

Drill pipe stand joint 3 joint

Substructure floor height 30 ft

Static hook load 1000000 in 10 lines

AC top drive 500 Tons

Rotary table torque 37.5 inch

Mud pump reciprocating triplex single 1600 HP each unit driven by 2 nos. DC traction motors 2×1100 HP) 3 Sets

- The technical and commercial proposal has been accepted for 2 sets of rigs.

- 5.8.2 well repair rig

OILMICO,2 sets land repair rig 1500 hp and 2sets land repair rig 1200 hp won in tender.

- Main parameters

Unfortunately,the all tender about rigs has been cancelled by client.

- Nominal Drilling Depth(Φ114mm (4½″) Drill pipe) 5000m

(Φ127mm (5″) Drill pipe) 4500m

- Max. Hook Load 3150 kN

- Drawworks Rated Power 1500HP

- Brake

Main brake Hydraulic Disk Brake (Water cooling)

Auxiliary Brake 436WCB2 EATON brake (Water cooling)

- Lines of Hoisting System 6×7(Clockwise)

- Dia. Of Drilling Line 35mm (1 3/8″)

- Rotary Table

Opening Size φ952.5mm (271/2″)

Speed 2

- Center Pipe Bore Hole of Swivel 76mm (3″)

- Mud Pump Power × Nos F-1300 Series 1300HPX3

Drive Path 2×600KW DC motor, Narrow V belt

- Mast Type & Height K Type,45m (148ft)

- Substructure Type Swing up

Height of Drilling Floor 9 m (29.5ft)

Area of Drilling Floor 13.3m×11.6m (43.6ft×38.1ft)

Height of Rotary Table Beam 7.6 m (24.9ft)

- Transmission Mode AC-SCR-DC Transmission

- Diesel Generator Sets CAT3512B